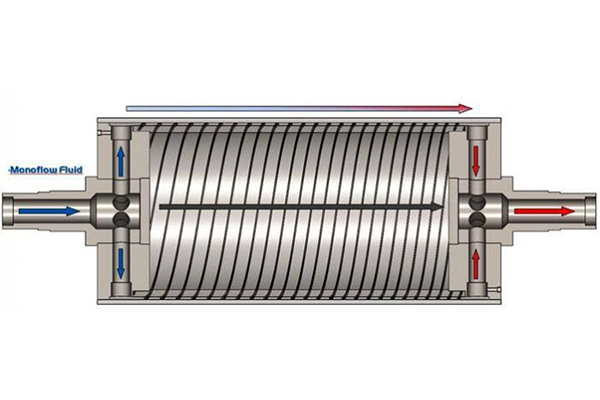

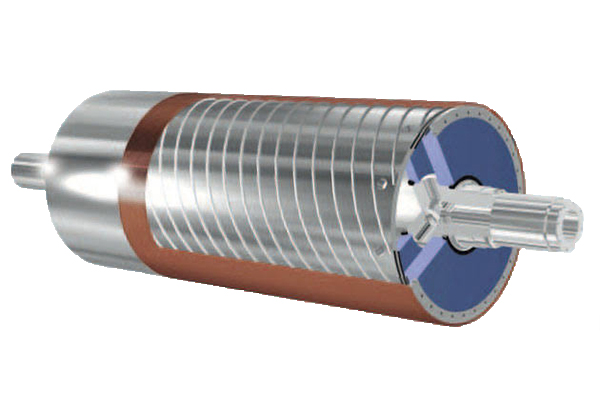

Rollers aka cylinders that can function at high temperatures and pressures are needed to meet the growing demand for manufacturing technologies that are faster and less thermally deviate. With the help of our design and engineering team, we manufacture the heating rollers to the specifications and tolerances specified by our customers. Our heating roller offers unmatched accuracy and controllability. This heated roll has several heater cartridges that are powered by a slip ring.

Characteristics of Heater Roller

| Material | Aluminum, Stainless Steel (S.S) |

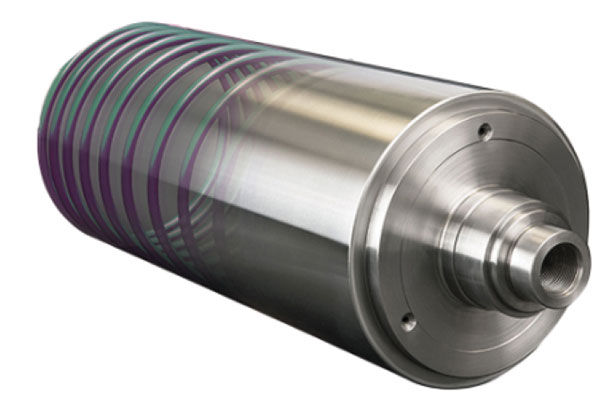

| Surface | Mirror Polished, Chrome Plated, Matt Polished, Rubber Coated |

| Roller type | Double Shell, Single Entry, Multiple Entry |

| Application | Textile, Printing, Conveyor Equipment, Paper, Oil |

| Roller Diameter | As per Requirement |

| Surface Coating | Hard chrome Plating, Mirror Finish |

Features of Heater Roller

- Heating elements that have been compacted for improved heat transfer and durability.

- Heating Coil made by using Nichrome 80/20.

- High quality MgO insulation powder for maximum heat transfer and electrical insulation.

- S. Terminal pins to stop terminals from burning and fusing.

- Quick heating is economical and conserves energy.

- Durable and long lasting.

- Each element can be easily replaced.

- To prevent surface contact or wear, the thermocouple is end mounted in the roll body and rotates with the roll.

- Independent thermocouple slip ring and heater assemblies.

- Mercury-wetted contacts are used in signal slip rings.

- The placement of the heaters ensures that the roll surface is heated evenly.

- There are manual and automatic controls available.

- Cantilevered design for materials with a small width